Dust Suppression Theory & Application

3rd October 2018

Dry fog fugitive dust suppression works like a combination of a wet scrubber and fabric filter. The generated ultra-fine fogging blanket acts like a fabric filter in that a dust particle cannot pass through it without colliding with a droplet. Since the droplet consists of water, the dust particle does become somewhat wet as in a true flooded scrubber. This phenomenon can be called agglomeration.

Solving fugitive dust emission problems using ultra-fine water droplet atomisation begins with the the theory of agglomeration. Agglomeration can be defined as the gathering of mass into a larger mass, or cluster.

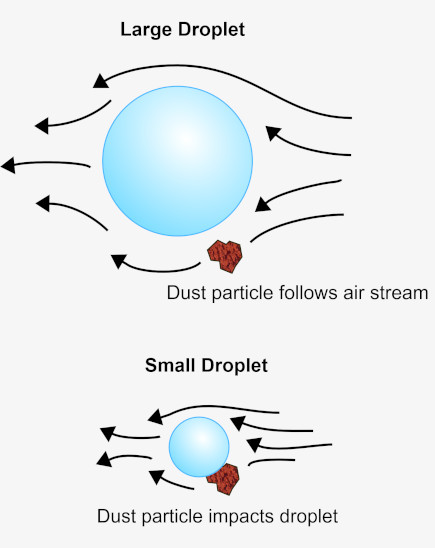

Agglomeration probability is greatly increased between bodies of similar size. The agglomeration of these bodies produces a large enough mass to cause settling. For example, a dust particle of 5 microns will continue to follow the air stream around a water droplet of 200 microns, therefore, avoiding collision. With the dust particle and a water droplet of similar size, the air stream is not as great and collision occurs, causing agglomeration.

Fog suppression is one method to optimise the application of water to dusty materials. These systems use special ultrasonic nozzles to produce extremely small water droplets (10 microns or less) in a dispersed mist. These droplets mix and agglomerate with dust particles of similar size, with the resulting larger combined particles falling back to the material body.

Dry Fog Dust Suppression Systems control virtually all types of less than 5 micron breathable as well as larger size fugitive dust up to 600 microns. Control is accomplished through agglomeration of ultrasonically produced water droplets equal or close to the size of the dust particles. These include silica sand, dried clay, dry sand, limestone, aggregate, road stone, phosphate, coal, quartz, fibreglass and many others. The Dry Fog System suppresses visible emissions from primary and secondary crushing, screening, transfer and loading/unloading facilities such as hoppers, feeders, bins, docks, silos, terminals and vehicles.

The sonicom atomising nozzle along with a compressed air supply and simple on/off controls will suppress respirable dust as small as 0.1 to 3 microns as well as larger size particles. The initial cost, operation and maintenance of a Dry Fog System is much lower than a ventilation type control system. In contrast to the use of large ducts and related equipment, the sonicom system operates with smaller diameter tubing on as little as 5% of the total energy of conventional systems. Dry Fog systems can be installed for as little as 40% of the installation cost of a conventional bag filter type system.

For more information on our dry fog systems, visit our Dust Suppression Systems page.